For Germany, and beyond.

Sheet metal and tube processing

for customers with

premium standards

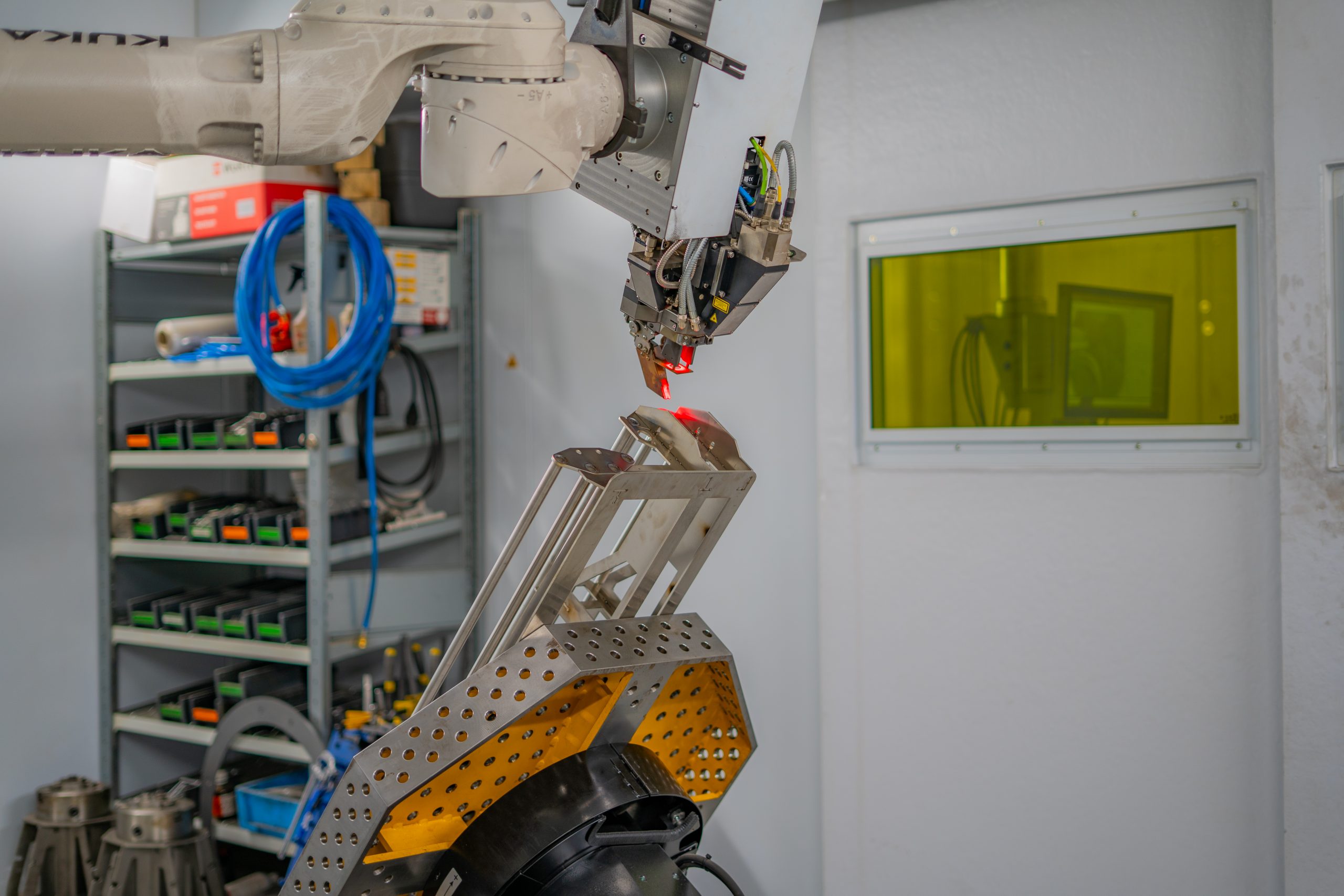

Innovative sheet metal processing – setting new standards

orders

The complete process chain for all industries

Whether sheet metal or tube – we offer the entire process chain from a single source: precise, flexible, and cross-industry. For us, quality isn’t a promise – it’s the standard. Together, we develop solutions that turn your vision into reality.

We provide personal consultation, dive deep into your requirements, and develop tailored solutions – using state-of-the-art technologies and a forward-thinking mindset.

Our services

Upon request, we can carry out the entire process chain or handle individual steps – just as you need.

What makes our service unique

Our in-house delivery fleet transports your components quickly and reliably – directly to you, within a radius of up to 200 km around our location.

With automated processes and modern machinery, we ensure maximum precision, short lead times, and optimal efficiency – for every single component.

We take time for your project, listen carefully, and support you with technical expertise – from the initial idea to the finished product.

Why choose us?

Transparent services with the highest standards.

Optimized workflows ensure short production times, maximum precision, and outstanding cost-effectiveness.

We rely on the latest technology to deliver precise results and maximum production reliability.

From the first cut to the finished product – everything from a single source, perfectly coordinated.

We go a step further: with know-how and experience, we make good products even better.

Follow us on social media

Where passion meets high-tech

What our customers say

AUSGEZEICHNETTrustindex überprüft, ob die Originalquelle der Bewertung Google ist. Verkauft ihr so einen Laserpointer auch?Gepostet aufTrustindex überprüft, ob die Originalquelle der Bewertung Google ist. Habe bis jetzt nichts mit der Firma zu tun. Möchte trotzdem ein Lob aussprechen für die Werbung der Firma. Mit dem Laser Strahl der in den Himmel projiziert wird wurde ich neugierig. Die Idee ist aufgegangen, Interesse zu erwecken. Das spricht für Innovation und verdient Respekt.Gepostet aufTrustindex überprüft, ob die Originalquelle der Bewertung Google ist. Hier befindet sich genau der Laser, den Sie suchen, wenn Sie auf der A2 unterwegs sind😂Gepostet aufTrustindex überprüft, ob die Originalquelle der Bewertung Google ist. Best Metal Workground around.Gepostet aufTrustindex überprüft, ob die Originalquelle der Bewertung Google ist. Zuverlässiger Geschäftspartner, sehr zu empfehlen.Danke!Gepostet aufTrustindex überprüft, ob die Originalquelle der Bewertung Google ist. Heute hatte mein Sohn einen Ausflug mit dem Kindergarten zur Firma ABP. Er hatte sehr viel Zubereiten. Es gab sogar eine Kiste mit kleinen Geschenken. Sehr schön das die Kids die Möglichkeit bekommen haben um sich die Firma anzuschauen. 😊

Our ideal location

We rely on our partners

Which industries do your customers come from?

We work across industries – that means almost all customers are welcome.

Whether it’s mechanical engineering, medical technology, architecture, or automation – we understand your specific requirements and deliver tailored solutions.

What location advantages does ABP offer?

Our location in Schopsdorf is directly connected to the A2 motorway, offering ideal access for fast deliveries and short routes.

We’re also in close proximity to numerous industrial and craft businesses – this creates synergies, saves time, and ensures smooth collaboration.

What is ABP’s typical customer radius?

In addition to companies in our immediate area, we regularly serve customers within a 200 km radius – including many medium-sized and industrial partners.

Beyond that, we operate throughout Germany and carry out projects across Europe.

Thanks to our convenient location on the A2 motorway, cooperation with Eastern European companies is also easily possible.

Our logistics are designed to deliver reliably and on schedule – no matter where you’re located.

What services do you offer in sheet metal and tube processing?

We cover the entire process chain of sheet and tube processing – from cutting, turning, milling, and bending to welding, laser cutting, and final surface finishing.

We rely on state-of-the-art machinery, digital processes, and consistent quality assurance.

Is ABP only a classic contract manufacturer?

No – we are much more than just a contract manufacturer.

As a system supplier, we support our customers from the initial idea to the finished component – with technical consulting, proactive planning, and reliable series production.

Our goal is to build real partnerships – not just process orders.

Can I join ABP as a career changer or start an apprenticeship?

Yes, absolutely!

At ABP, we believe that motivation, willingness to learn, and team spirit are just as important as a traditional résumé.

Whether you’re switching careers or just starting out – everyone has the chance to grow within a modern, future-oriented company.

We also train apprentices in several areas and guide young people on their way into the professional world – with hands-on experience, real support, and long-term perspective.

Those who start with us, start with momentum.

Innovative sheet metal processing from Schopsdorf – precise, flexible, and reliable. Your partner for metalworking.

© 2025 ABP – Innovative Blechbearbeitung GmbH. All Rights Reserved

| Entwicklung & Umsetzung: conceptmedia