Description and specifications

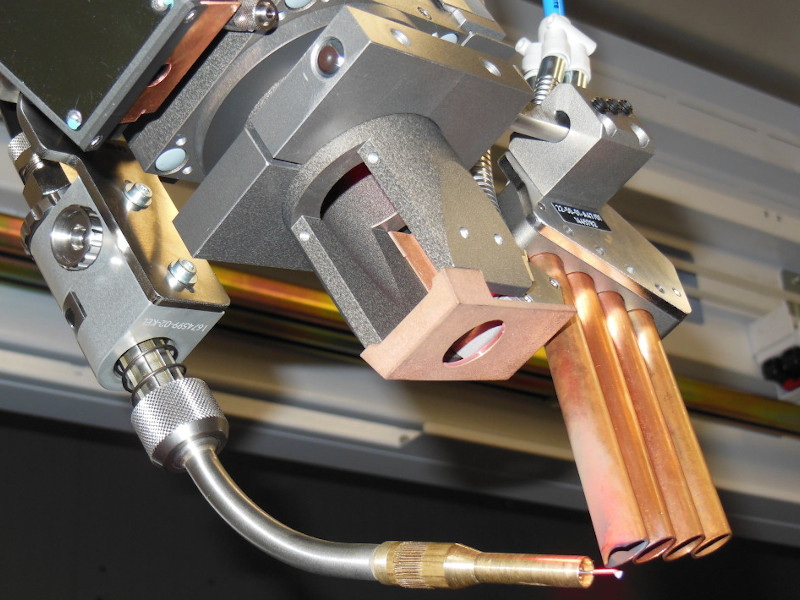

The process of laser cutting

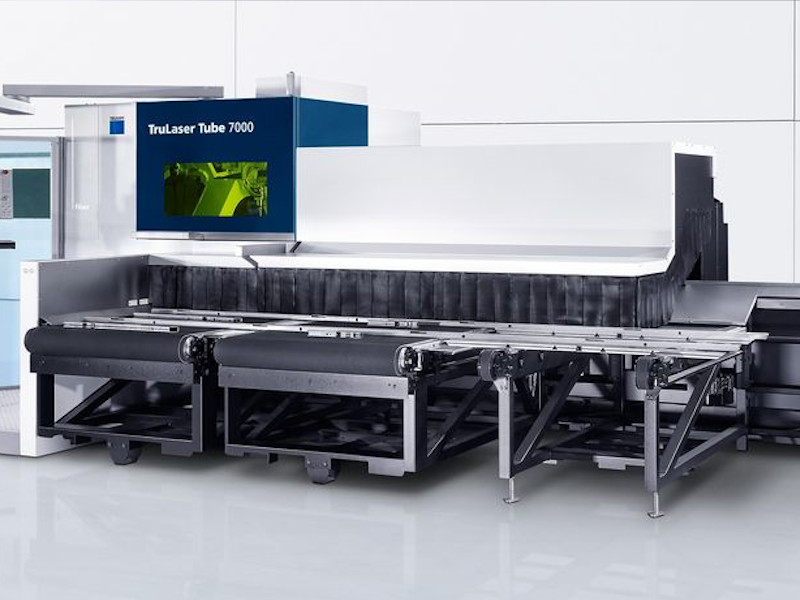

Our flatbed laser machine, also from Trumpf, is used to form the blank outline, the first step of the process. The system offers 4 KW performance. We work exclusively with CO2 laser technology. Sheet formats up to 1.5 x 3 meters can be processed. To use the laser system efficiently, a LiftMaster is available for loading and unloading the sheets.

1. TruLaser 3030

- 4 KW cutting power

- Structural steel, stainless steel & aluminum can be processed

- Max. Sheet format 1.5 x 3.0 meters

- Liftmaster with double carriage

- Automatic nozzle changer

- Single cutting-head strategy (set-up optimization)

- RotoLas pipe cutting unit; pipes from Ø15 – 310 mm* can be processed*

* Rectangular tubes must not exceed the geometrical diagonal of 310 mm. Talk to us about the available options we can offer!

2. Deburring technology for stainless steels and aluminum

After cutting, materials are processed using the WEBER deburring machine. We guarantee our customers a consistent, visually appealing cutting quality.